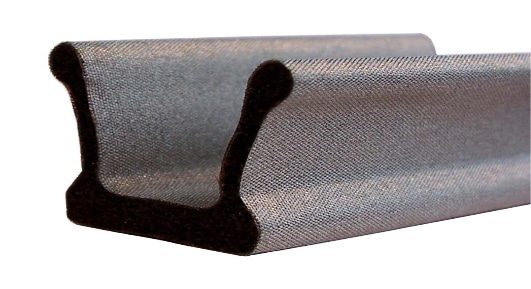

EMI gaskets and EMI shield tape are two different types of materials used for electromagnetic interference (EMI) shielding. EMI gaskets are made of conductive materials and are used to create a physical barrier between electronic components to prevent EMI from passing through gaps and seams in the equipment. On the other hand, EMI shielding tape is a self-adhesive tape made of conductive materials that can be used to shield electronic components and enclosures from EMI.

EMI gaskets and EMI shield tape are two different types of materials used for electromagnetic interference (EMI) shielding. EMI gaskets are made of conductive materials and are used to create a physical barrier between electronic components to prevent EMI from passing through gaps and seams in the equipment. On the other hand, EMI shielding tape is a self-adhesive tape made of conductive materials that can be used to shield electronic components and enclosures from EMI.

When to use EMI gaskets:

- When there are gaps or seams between electronic components or enclosures that need to be sealed

- When the equipment needs to be able to withstand physical stresses, such as vibration or impact

When to use EMI shield tape:

- When there are no gaps or seams to seal, but the equipment still needs EMI shielding

- When the equipment does not need to withstand physical stresses

In general, EMI gaskets are more effective at blocking EMI than EMI shielding tape, but they are also more expensive and may require more time and effort to install. On the other hand, EMI shielding tape is easier and cheaper to use but may not provide as much EMI protection as a gasket. Ultimately, the choice between EMI gaskets and EMI shielding tape will depend on the specific needs of the application and the constraints of the project, such as budget and time.

If you’re looking for materials to block electromagnetic interference, reach out to us. We can help you decide what will work best for your needs. We’ll help you choose between EMI gaskets and EMI shield tape.